Introduction & Why PPE Matters

Introduction

Workplace accidents can happen in the blink of an eye, but their consequences can last a lifetime. Whether it’s a slip, a fall, or exposure to hazardous substances, these incidents often lead to long-term health issues or even fatalities. One of the most effective ways to prevent serious injuries is by using Personal Protective Equipment (PPE).

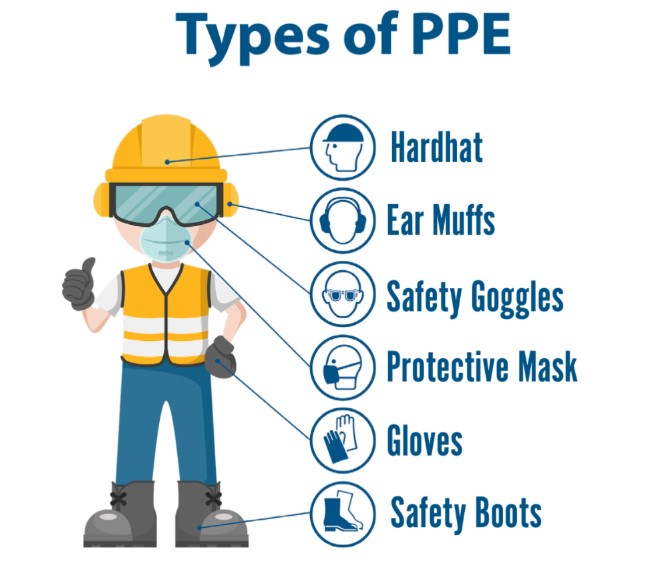

From helmets and gloves to respirators and safety boots, PPE acts as the last line of defense against workplace hazards when engineering controls (like safer equipment) and administrative controls (like training) are not enough to eliminate risks.

PPE is essential in creating a safe working environment, ensuring that workers are protected from injuries that may occur despite other safety measures.

What is PPE?

Personal Protective Equipment (PPE) refers to gear designed to protect workers from injuries and illnesses caused by various workplace hazards. These hazards may include:

Chemical exposure (e.g., acids, solvents, cleaning agents)

Falling objects (e.g., from construction sites)

Sharp tools and machinery (e.g., knives, saws)

Noise and dust (e.g., construction, industrial work)

Extreme temperatures (e.g., welding, refrigeration)

PPE helps minimize the impact of these hazards, providing an extra layer of protection that reduces the risk of serious injuries and health problems.

Why PPE is Essential

Without proper PPE, workers are at a greater risk of occupational injuries that could have been easily prevented. According to the International Labor Organization (ILO), over 2.78 million workers die annually due to workplace accidents and diseases. Many of these deaths and injuries could be avoided with the proper use of PPE.

It is the employer’s responsibility to provide suitable PPE for their workforce and ensure it is used consistently and correctly. However, it’s equally important for employees to understand the necessity of PPE and the potential consequences of non-compliance.

How PPE Prevents Workplace Injuries

PPE provides a critical layer of defense in protecting workers from a wide range of hazards. Depending on the type of PPE, workers are protected from physical injuries, chemical exposure, biological hazards, and environmental stressors. Below are examples of how PPE prevents specific injuries:

1. Protection from Physical Hazards

Safety helmets, gloves, and steel-toe boots protect workers from cuts, crush injuries, and falls caused by heavy tools, machinery, or debris.

In construction or manufacturing, workers may face falling tools or equipment, and these injuries can be mitigated with appropriate protective gear.

2. Chemical and Biological Protection

Chemical-resistant gloves, face shields, and full-body suits are designed to protect workers from hazardous chemicals and biological agents.

In industries like pharmaceuticals, waste management, or laboratories, exposure to harmful substances can lead to chemical burns, poisoning, or infection. Wearing the right PPE prevents direct contact with harmful materials.

3. Respiratory Safety

Respirators and masks protect workers from inhaling toxic fumes, dust, and airborne particles that can cause lung damage and respiratory illnesses.

Industries like construction, mining, and paint manufacturing often involve tasks that produce hazardous dust or fumes, making respiratory protection essential. Workers who handle materials like asbestos, silica, or chemicals are particularly vulnerable to lung diseases if they are not adequately protected.

4. Eye and Face Safety

Safety goggles and face shields are crucial for protecting workers from flying debris, sparks, and harmful light radiation (such as during welding, grinding, or cutting activities).

These protective items prevent chemical splashes, dust particles, and heat exposure from causing permanent eye damage or facial burns.

5. Hearing Protection

Earplugs and earmuffs reduce the risk of noise-induced hearing loss in loud environments, such as factories and construction sites.

Prolonged exposure to noise above 85 dB (a threshold set by OSHA) can lead to permanent hearing loss. PPE such as earplugs or earmuffs minimizes exposure to high-decibel sounds, preserving hearing health.

Real-Life Example

A construction company was able to reduce head injuries by 80% within a year after enforcing a mandatory helmet policy for all workers and visitors on site. Prior to this, many workers had opted not to wear helmets in non-hazardous areas, and the company faced several claims related to head injuries. Once the helmet policy was implemented, compliance increased significantly, leading to a dramatic drop in injuries.

This example highlights how simple PPE policies can have a major impact on workplace safety, especially when enforced consistently.

Best Practices for PPE Use

While providing PPE is crucial, employers must also ensure that workers use it correctly and consistently. Here are best practices for PPE use:

1. Training & Awareness

Employees should receive PPE training to understand proper usage, maintenance, and limitations.

Regular training sessions should be held to keep workers updated on any changes in safety procedures and to emphasize the importance of correct PPE usage in various work environments.

2. Regular Inspections

Damaged or expired PPE should be replaced immediately to maintain protection.

Periodic inspections should be conducted to check for signs of wear, ensuring that PPE continues to meet safety standards and remains effective.

3. Correct Fit

Ill-fitting PPE can cause discomfort and reduce its effectiveness. Workers should ensure that their protective gear fits properly and does not impede movement or cause excessive discomfort.

Employers should provide multiple sizes and allow workers to select the most suitable PPE for their body types.

4. Cleanliness & Storage

PPE must be cleaned regularly and stored properly to avoid contamination and maintain its effectiveness.

Workers should be educated about proper cleaning methods and should have access to cleaning supplies and storage facilities.

5. Policy Enforcement

Supervisors and managers must ensure PPE compliance at all times, especially in high-risk environments. Regular safety audits can be used to ensure that safety protocols are being followed and that PPE is used correctly.

Conclusion

Personal Protective Equipment (PPE) is a critical part of any workplace safety program. However, it is most effective when combined with hazard elimination, engineering controls, and administrative measures. By investing in high-quality PPE, ensuring workers are properly trained, and enforcing PPE policies, employers can drastically reduce workplace injuries and fatalities.

PPE protects workers, ensuring that they are safe from hazards that may not be immediately visible or obvious. By making the right investment in safety measures and ensuring compliance, employers are not just protecting their workforce—they are investing in the long-term health and productivity of their business.

Workplace safety doesn’t have to be complicated; the key is consistent monitoring, proper training, and a commitment to safety. PPE is an essential tool in keeping workers safe and healthy, and with the right policies in place, employers can safeguard their workforce and improve overall operational performance.