Understanding Heat Stress in the Workplace: A Hidden Danger

Heat Stress: Understanding and Preventing the Silent Threat

When temperatures soar, so do the risks for workers, especially those who work outdoors or in high-temperature environments like kitchens, factories, or construction sites. Heat stress is more than just discomfort—it can quickly escalate into a medical emergency if not managed properly. Heat stress affects the body’s ability to regulate temperature, leading to severe illnesses that can be fatal if not addressed in time.

What is Heat Stress?

Heat stress occurs when the body can no longer cool itself through sweating and other natural cooling mechanisms. This imbalance leads to heat-related illnesses. The severity of heat stress can vary, and if left unchecked, it can quickly become life-threatening. Common heat-related conditions include:

Heat Rash: This irritating skin condition is caused by excessive sweating, leading to blocked sweat ducts and inflammation. It commonly appears as small red bumps or blisters on the skin.

Heat Cramps: Heat cramps are painful muscle spasms, usually in the arms, legs, or abdomen. These cramps are caused by a loss of salt and water through excessive sweating, often aggravated by dehydration.

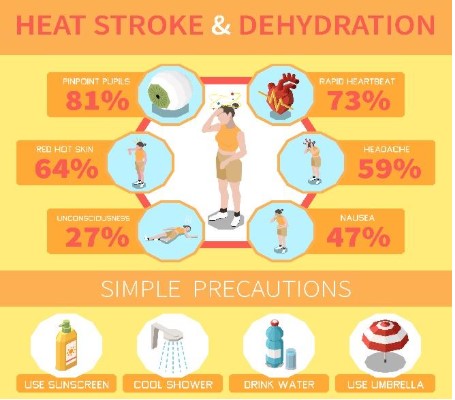

Heat Exhaustion: This condition is characterized by symptoms such as dizziness, nausea, headache, fatigue, and a rapid heartbeat. It occurs when the body loses too much water and salt, impairing its ability to cool itself down. Heat exhaustion can progress to heat stroke if not treated promptly.

Heat Stroke: Heat stroke is the most serious form of heat stress and is a life-threatening emergency. The body’s core temperature rises above 104°F (40°C), and normal cooling mechanisms fail. Symptoms include confusion, loss of consciousness, seizures, and hot, dry skin. Heat stroke can cause organ damage, brain injury, or even death if not treated immediately.

Who Is at Risk?

Heat stress can affect anyone working in hot environments, but some groups are at higher risk:

Outdoor Workers: Workers in construction, agriculture, and landscaping are often exposed to direct sunlight for prolonged periods. The risk is higher for those working on hard surfaces that absorb heat, such as concrete or asphalt.

Indoor Workers: Kitchens, factories, and warehouses with poor ventilation or without air conditioning can create environments where heat stress is prevalent. These spaces can trap heat, making it harder for workers to cool off.

Workers Wearing Heavy PPE: Personal protective equipment (PPE), such as fire-resistant clothing, helmets, gloves, and protective suits, can trap heat and make it harder for workers to sweat effectively. PPE is essential for safety but can increase the likelihood of heat stress, especially in hot environments.

New Employees: New hires or employees returning after a long absence need time to acclimatize to the heat. Without gradual exposure, their bodies are more susceptible to heat stress during the early days of their employment.

Prevention: Key HSE Practices

Prevention is key to reducing the risks associated with heat stress. Below are some best practices that employers and workers can implement to minimize the chance of heat-related illness:

1. Hydration is Critical

One of the most effective ways to prevent heat stress is through hydration. Encourage workers to drink water every 15–20 minutes, even if they don’t feel thirsty. Water helps maintain the body’s cooling mechanisms and prevents dehydration, which can contribute to heat exhaustion. Avoid caffeinated or alcoholic drinks, as they can cause dehydration.

2. Schedule Smart

Scheduling work during the cooler parts of the day—such as early morning or late evening—can reduce exposure to extreme temperatures. Avoid scheduling heavy physical work during peak heat hours (typically from noon to 3 p.m.), when the sun is at its hottest. Consider shifting high-intensity tasks to the cooler hours, and provide regular breaks throughout the day.

3. Dress for the Weather

Workers should wear light-colored, loose-fitting, and breathable clothing to allow for better air circulation and sweat evaporation. Light-colored clothing reflects sunlight and helps prevent the body from absorbing additional heat. Where applicable, consider allowing workers to wear cooling vests or neck towels to further regulate body temperature.

4. Train & Educate

Training is essential in ensuring that workers and supervisors recognize the signs of heat stress and understand how to respond quickly. Teach workers about the early symptoms of heat-related illnesses, such as dizziness, nausea, and confusion. Educate them on first aid response steps and emphasize the importance of stopping work immediately if they experience any symptoms.

5. Use the Buddy System

Assign workers to buddy systems where each worker is responsible for monitoring the well-being of their partner. The buddy system helps identify early signs of heat stress that a worker may not recognize in themselves. Supervisors should also encourage workers to keep an eye on each other for signs of fatigue, dizziness, or confusion.

6. Provide Cool Rest Areas

Ensure that workers have access to cool, shaded rest areas. Air-conditioned rooms, shaded tents, or portable fans can provide respite for workers who need to recover from the heat. It’s important to provide enough time for workers to rest and rehydrate before continuing their tasks.

What Employers Must Do (According to HSE Guidelines)

Employers are legally and morally responsible for ensuring a safe workplace, particularly in high-risk environments. According to HSE (Health and Safety Executive) guidelines, employers should:

Conduct a Heat Risk Assessment

Identify areas with high heat exposure and assess the risk levels in these environments. This should include monitoring temperature, humidity, and radiant heat levels. Ensure that workers are aware of these risks.Implement Control Measures

Provide adequate shade, fans, or cooling systems to mitigate high temperatures. Where possible, rotate tasks to reduce the amount of time workers spend in hot areas. Scheduling work during cooler parts of the day or adjusting the intensity of work can further minimize the risks.Provide PPE like Cooling Vests Where Needed

Depending on the work environment, employers may need to provide specialized PPE that helps cool workers, such as cooling vests, moisture-wicking clothing, or portable misting fans.Maintain Incident Logs and Follow Up After Any Heat-Related Issue

Keep a record of any heat-related incidents or near misses. Review these incidents regularly to identify trends and areas where safety measures can be improved.

Conclusion: Heat Stress is Preventable

Heat stress is preventable, yet it continues to cause injuries and fatalities worldwide. By implementing a Heat Stress Prevention Program, employers can protect workers from heat-related illnesses and ensure they stay healthy and productive.

Remember, prevention is always better than treatment. Regular training, smart scheduling, proper hydration, and the right PPE are all essential components of an effective heat stress prevention program. A little extra effort in preparing for heat can save lives and prevent long-term health complications. Ensure that every worker has the tools and knowledge they need to work safely, even in extreme heat.